Our Motorcycle Parts New Zealand Specialists Statements

Table of ContentsUnknown Facts About Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedGetting My Motorcycle Parts New Zealand Specialists To WorkThe Facts About Motorcycle Parts New Zealand Specialists UncoveredThe Best Guide To Motorcycle Parts New Zealand SpecialistsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingThings about Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand Specialists

So, get to out to one of our professionals today.CNC machining technology is promptly coming to be the prime focus of various production procedures around the globe as a straight result of its several benefits over various other methods. Furthermore, the industries that produce motorcycles have actually gotten on board with this pattern. The most innovative business are currently developing their engine parts and wheels utilizing machining methods initially established for motorcycle parts.

On the other hand, the results of market are the key emphasis of this post. Allow's get directly right into it. You may be asking yourself why we use. It is not difficult to fathom the factors that caused this outcome. Currently that we have your interest allow us explain the rationale behind this contemporary growth in the bike manufacturing market.

The Motorcycle Parts New Zealand Specialists Statements

In enhancement, you have full control over the appearance of the components, also down to the minute information. Sometimes, motorcyclists may decide to spruce up their experience by installing aftermarket parts or customizing the bike's makeover.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

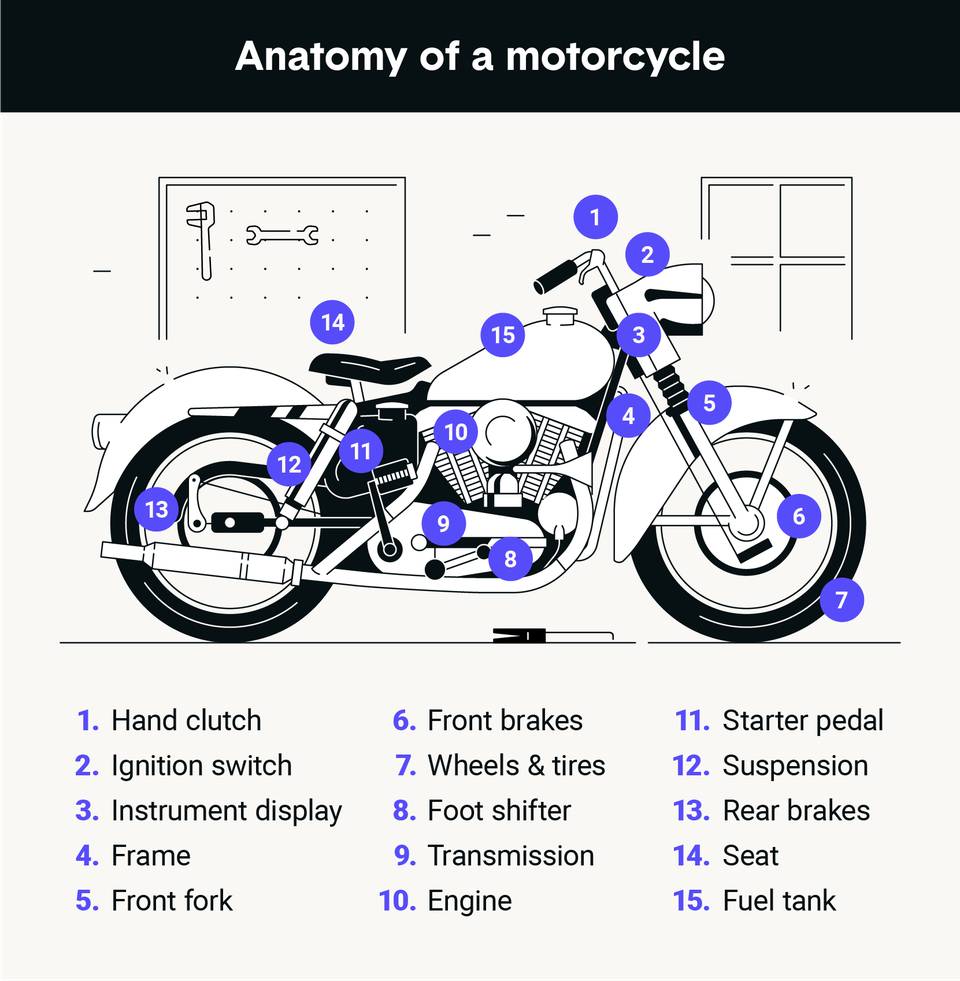

CNC machining may be utilized to make nearly all of a motorbike's steel and plastic parts. To proceed, we'll go over several machined parts for motorbikes. Unlike those on automobiles, wheels on bikes have a tendency to be much more evident. As an outcome, the bike's appearances may be enhanced with the proper modification of these wheels.

Milling procedures are made use of to get the wanted degree of wheel modification. Another aspect of the bike that may be customized is the tires.

The Only Guide to Motorcycle Parts New Zealand Specialists

When it comes to a car (or a motorbike), one of the most crucial part is the engine. Numerous individuals mention it as the "heart" of the auto. On the other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be elaborate and call for styles with a high level of precision.

Use only premium products, nonetheless, because these lights are crucial for the safety and security of motorcyclists and various other chauffeurs or individuals on the road, specifically at night. Motorbike fronts lights have three major components: the light bulb, or light resource, the lens, and the housing.

Milling procedures with a flawless finish would certainly result in the lenses having a reflective high quality that resembles that of a mirror. The cover, on the other hand, is not composed of breakable products; rather, it is constructed out of hard polymers that can be machined right into more complex patterns.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

They commonly have sophisticated geometries with a riches of minute information. Motorbike producers typically cast these elements, but just for the manufacturing of bespoke parts. Nevertheless, CNC machining is the approach of option when creating distinct pieces. Machining on 5 axes in today's world is the means by which any design shape might be realized.

Pick Runsom for your personalized motorbike components! We have the capability to make complex and fashionable parts making your motorbike incomparable.

Below are a few instances of steels typically utilized in bike part machining. Light weight aluminum is the primary material used by companies specializing in creating personalized bike elements to produce most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more metal that is really light in weight and has see this page fantastic machining top qualities because of its high mechanical toughness. This material might be formed right into virtually any type of form and keeps its measurements well. Even mission-critical elements that require a high degree of precision may take advantage of their use.

A Biased View of Motorcycle Parts New Zealand Specialists

Another metal that sees hefty usage in the production of CNC-customized components is magnesium. It is among the lightest steels that are currently easily accessible and has outstanding machinability functions and toughness commensurate with its reduced weight. Among the drawbacks of magnesium is that its dust right here might easily capture fire.

Their most usual usage in producing different bike parts is fasteners, such as screws and bolts. Their reduced susceptibility to oxidation and rust makes them suitable for this usage.

The Only Guide for Motorcycle Parts New Zealand Specialists

It seems that CNC turning and grating are the fundamental procedures. In addition, it requires keeping bars of product, most usually plastic or metal, in position and then turning a cutting tool to get rid of areas of the product as the material is transformed.

These methods are similarly crucial and create elements with high accuracy and constant high quality. The procedures help boost the general top quality of the machined motorbike elements.

Top Guidelines Of Motorcycle Parts New Zealand Specialists

Comments on “The Best Strategy To Use For Motorcycle Parts New Zealand Specialists”